Recent failures of shore side bollards that cast moored vessels adrift has the Coast Guard urging terminal operators to inspect for deteriorated material conditions in bollards, their foundations and fasteners.

Vessels and shore side facilities have been damaged in the incidents, but no deaths or injuries reported. Neither the Coast Guard nor the Occupational Safety and Hazard Administration (OSHA) have regulatory authority over those dockside anchors for mooring lines – so it’s up to mariners and terminal operators to check for the danger.

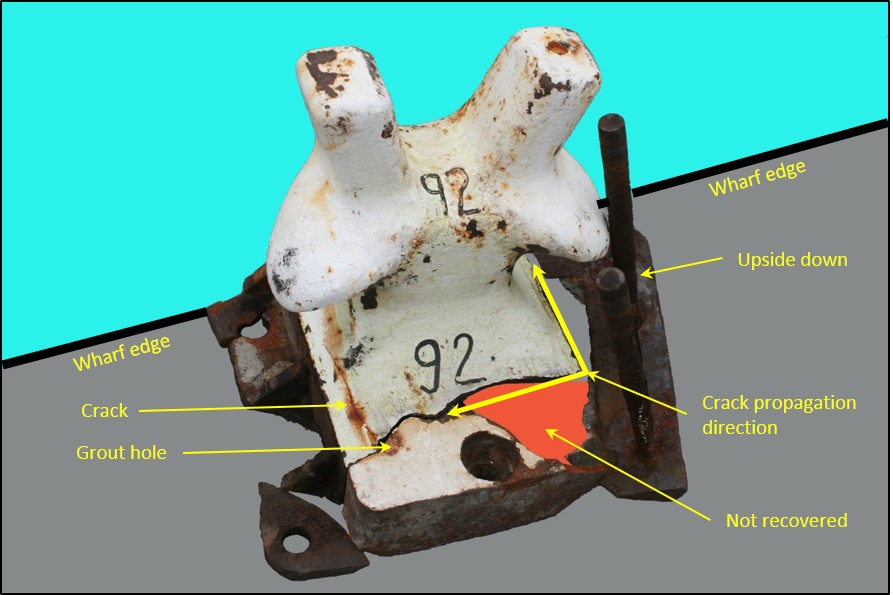

A corroded base and fasteners on a failed steel bollard. Coast Guard photo.

“Causes include the rotting of organic bollards made of marine pilings, the undetected fracture of bollard castings due to manufacturer defects, damage from previous overloads, or the degradation of bollard foundations and fasteners. Typically, the failures are associated with abnormal dynamic loads transferred to the bollard from a vessel.”

Those loads can be brought by winds acting against the broadside sail areas of large ships – which are substantial for the new generation of cruise ships and very large containerships when the weather turns gusty.

In a windy mid-May incident at Port Newark, N.J., the 984’x149’, 8,004- TEU Hapag-Lloyd containership Tucapel broke mooring lines as it moved toward a berth. The ship had to drop anchor and be stabilized with assistance from four tugboats.

In August 2014, two vessels broke free at the Port of Fremantle in Australia when a passing thunderstorm pushed on the ships, and a bollard holding both their stern lines broke. The vessels were recovered by tugs with minor damage, but one bumped into a rail bridge that had to be closed for three weeks.

Coast Guard officials recommend that facility owners and operators “take steps to develop a routine inspection program for bollards and other mooring equipment. Furthermore, vessel personnel should report discoveries of apparently deficient shore side mooring equipment to facility manage