A Half Century of Aluminum-Steel Success: Naval Shipbuilders & Detacouple™

For decades, naval architects faced complex decisions when designing maritime vessels with different metals, weight, and corrosion-resistant priorities all within defined structural design budgets. To balance these priorities, shipbuilders often joined dissimilar metals with mechanical fasteners, which accelerated topside and splash zone corrosion in crevices.

Innovation at Work: Explosion Welding & Detacouple™

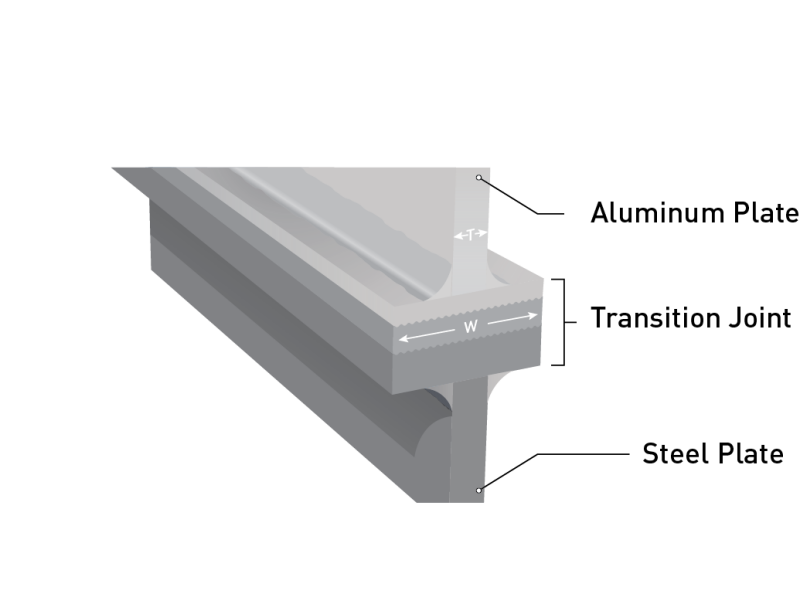

Understanding these challenges, DuPont developed and patented explosion welding in 1962. The precise, ‘solid-state’ welding technology uses explosive detonation to metallurgically join dissimilar metals, while retaining the mechanical, chemical and electrical properties of both metals.

In partnership with the U.S. Navy, DuPont further pioneered explosion welding and developed aluminum-to-steel clad strips, known today as Detacouple structural transition joints. Detacouple offered shipbuilders an alternative to corrosion-prone mechanical fasteners: metallurgically welded, crevice-free, aluminum-steel transition joints that could withstand harsh environments.

By the late 1960s, after extensive testing, Detacouple structural transition joints gained U.S. Navy approval and the aluminum-steel clad strips quickly began replacing mechanical fasteners in shipyards across much of North America. Nearly all American and Canadian naval vessels built after 1970 contain Detacouple® structural transition joints, as do thousands of today’s commercial shipbuilding applications.

Choosing an Experienced, Proven Partner Matters

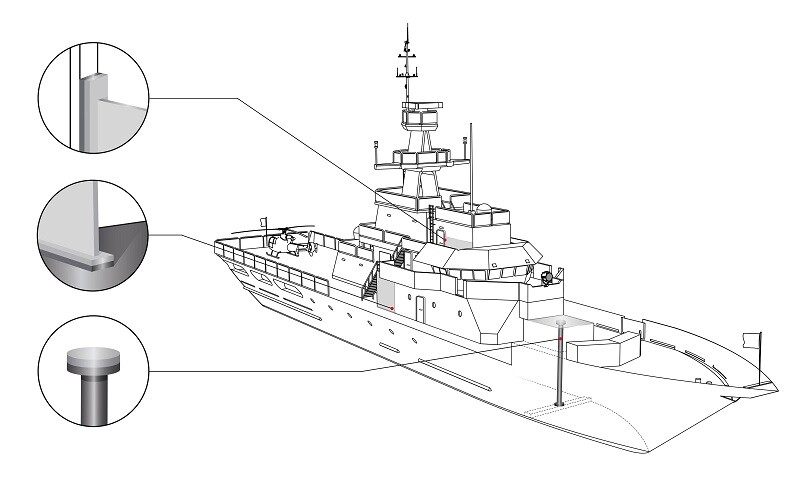

Because naval vessels operate in highly corrosive environments, equipment failure can mean loss of life, harm to the environment and significant financial loss. By choosing a trusted clad partner to guide them throughout the process—from specification and testing to delivery and maintenance support—naval architects, who still face complex decisions, avoid these pitfalls.

With decades of experience, NobelClad is the proven leader in explosion welding and offers the widest collection of customizable clad metal products in the world. Our history and reputation for quality and integrity are why naval architects continue to rely on our Detacouple structural transition joints to:

- Join aluminum superstructures to steel decks

- Join aluminum decks or bulkheads to steel hulls

- Fit components, such as pillars or walls, between steel or stainless steel and aluminum

- Fit steel components, such as engine mounts, to aluminum hulls

Learn More

The future is bright for naval architects who are reimagining the world powered and sustained by structural transition joints. NobelClad is here to support you with the design, purchase, and installation of Detacouple for your next ship building project.

NobelClad is exhibiting at The International Workboat Show in New Orleans. If you plan to be at the show December 1st – 3rd, stop by our booth #335. We hope to see you there.

If your team is new to learning about Detacouple, we would be happy to host a free introductory seminar on Detacouple for ship building. Fill out this form – and a NobelClad expert will contact you soon to schedule your 45-minute webinar.