Exhibitor Product News: “Delta” style stainless steel workboat props

One of our most successful and popular propeller designs for inland river service is the Kahlenberg “Delta” style propeller, with blade area maximized at the blade tips. Recently more popular again with variations from many manufacturers, this is a design we have been producing for more than 50 years.

What is new is HOW the “Delta” propellers from Kahlenberg are made, now with the latest design and manufacturing technology available in the industry.

Using a combination of state-of-the-art predictive software and previous experience, Kahlenberg confidently specifies a propeller with the geometric properties best suited for your application. Hydrocomp Prop Expert sizing software and PropCad software are utilized in the design process.

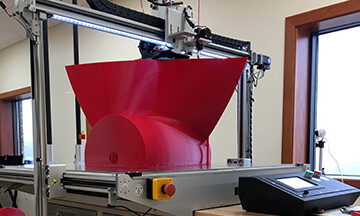

From the design phase, the original geometric data is exported to 3D modeling software, where it is refined and output to 3D Printing software, for creation of 3D Printed patterns. These printed patterns are then used for accurate molding of the propeller at the foundry. This new process results in a casting far more accurate as compared to the traditional techniques of the past.