It has been over four years since the Gulf of Mexico offshore slump began. But at November’s International WorkBoat Show there was little talk about hard times. Instead, I witnessed a lot of people running around with no time to chat. Why? They were busy conducting business.

A good indicator of how business will be in the future are the shipyard booths. This year, like last, their booths were buzzing with people inquiring about what the yards can build and when. Yards, especially those in the Gulf, are continuing to diversify, a trend that started after the offshore downturn began. More and more, these yards are going after hot sectors like passenger vessels.

A relatively new sector that shows promise is offshore wind. For the first time, we featured a session on the subject at the show, part of our Offshore Program. Offshore wind energy development is moving apace in the Northeast, and the U.S. Gulf can be a source of boats and skills for the new industry. This could mean more work for Gulf shipyards and vessel operators.

“What we would like to see is more of the expertise held here move to this market,” Ross Tyler, executive vice president and co-founder of the Business Network for Offshore Wind, told Offshore Program attendees. Tyler’s group includes U.S. industrial suppliers who could help develop the wind industry. “There’s a market there and we can be a conduit.”

Designers, builders and propulsion companies all had their eyes on offshore wind and hybrid marine power at the show. “Hybrid technology is where everybody is trying to go,” said Adam Jost, applications manager with Thrustmaster, the Houston-based propulsion integrator whose show display was built around its latest electric pod thruster design.

Over at the American Bureau of Shipping booth, Domenic Carlucci explained what ABS is doing to assist customers making the move to hybrid power systems.

“We’re seeing a lot of ferry work,” said Carlucci, manager of machinery, electrical and controls, and advanced technology and research for ABS.

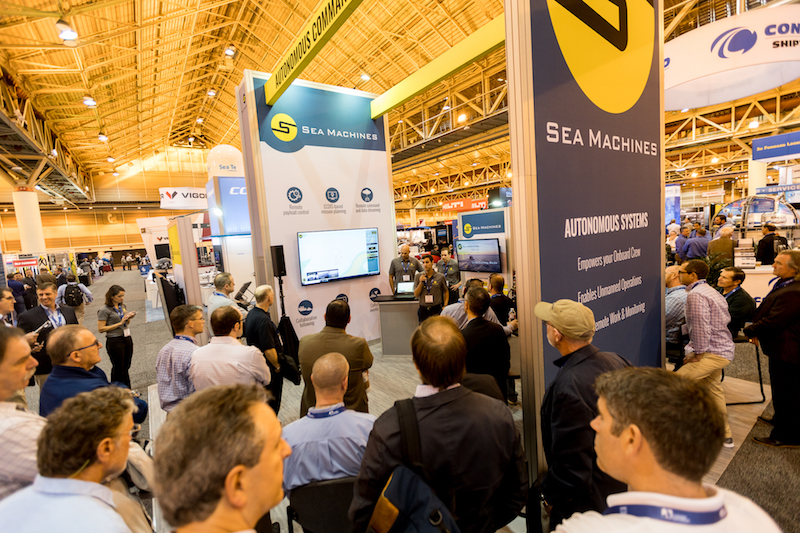

A still-developing technology is autonomous vessels, which was the subject of one of the Think Tank sessions at the WorkBoat Show.

Thinking about mating solar energy panels and electric drives to autonomous patrol boats raises the prospect of picket vessels with ultra-long endurance, said Chris Allard, CEO of Metal Shark, which this year unveiled its first Defender-class patrol vessel equipped with ASV Global technology.

“If you take away the two to four gallons per hour for stationkeeping, we’ve done scenarios where it’s startlingly close to infinite,” said Allard.

Autonomous functions will complement navigation bridge crews, effectively extending eyes and ears with their sensors, said Michael Johnson, founder and CEO of Sea Machines with offices in Boston and Hamburg.

Sea Machines is now working with Maersk to conduct sea trials on autonomous technology in that role on a crewed containership in the Baltic. Johnson and Allard say the technology can apply as a smart autopilot, alerting human operators to changing vessel conditions and external factors.

Hybrid, wind power and autonomous technology should continue to grow, and WorkBoat and the WorkBoat Show will be there to foster that growth.