In February, the University of Delaware’s 146', 19-year-old research vessel Hugh R. Sharp was hauled out at Colonna’s Shipyard Inc., Norfolk, Va., for a $1.9 million overhaul, including rebuilt Schottel Z-drives, bowthruster, and four diesel-electric generators.

The boat also received a new external look. Coatings from Sherwin-Williams, Cleveland, were selected under former marine operations director John Swallow and applied under successor David Walter.

The bilge and exterior were sandblasted, cleaned, and repainted with university colors. Below the waterline, the yard used Sea Guard 6000 on the hull and Sher-Loxane above the waterline. On deck surfaces, Sea Guard was infused with a mesh aluminum oxide aggregate for improved traction in the nonskid. The overall cost for the paint was about $30,000.

THE STANDARDS

International, a brand from AkzoNobel NV, Amsterdam, has long provided coatings to the commercial marine sector. For higher fouling zones, International offers Intersmooth 7670 SPC, copper-free Interspeed 5640 for aluminum hulls, and Interspeed 640 as a cost-effective alternative.

“We have found recently that our customers are increasingly looking to choose higher-performing coating solutions to meet new regulatory requirements,” an International spokesperson said. “Our forecasting tool, Intertrac Vision,” a big data tool assessing the impact of fouling control coatings on fuel use and emissions, “is helping customers make choices in complex regulatory environments simple and effective.”

The biocide-free Intersleek series, including 1100SR — applied to hulls as well as also used on propellers and running gear — has helped reduce shipowners’ fuel costs by more than $3 billion, according to the manufacturer.

For tanks, Interline 994 is a chemical-resistant epoxy novolac phenolic. Other options include products with low volatile organic compound (VOC) levels such as ZERO VOC preconstruction primer and Interplate ZERO. Intershield 300 has been used as a ballast-tank coating and Interline 850 or 975 would be applied to potable water reservoirs. Interline 704HS is the brand’s recommendation for heavy fuel oil or diesel, while methanol tanks get treated with Interline 344 or Interzinc 22HS.

PPG Industries Inc., Pittsburgh, offers a broad portfolio of marine coatings. Sigmashield 880, a surface-tolerant, abrasion-resistant epoxy, is commonly used in a single coat. Sigmashield 880 GF adds glass flake for improved resistance to cracking and sagging — ideal for workboat decks, according to the manufacturer. PSX 700, a low-VOC polysiloxane-epoxy hybrid, offers UV protection and abrasion resistance, making it suitable for high-exposure areas.

For antifouling, PPG’s ABC 3 is a self-polishing, organotin-free coating that helps reduce drag and meets IMO environmental standards. Nexeon 610 offers copper-free antifouling in a similar self-polishing formula. Sigmaglide 2390 is a biocide-free coating that uses HydroReset technology to form a smooth surface resistant to marine growth. “It can deliver up to 35% emission reduction and enhance vessel energy efficiency,” said Josh Stinson, PPG commercial marine regional sales manager, protective and marine coatings.

PPG stands out in offering products like Sigmaglide and Nexeon that can be applied electrostatically — a process that directs charged paint particles to the grounded vessel surface, minimizing overspray and reducing waste.

For running gear, PPG offers Sigmashield 1200, developed for ice-going vessels. The reinforced, solvent-free epoxy phenolic coating combines anticorrosive properties with high polymer cross-link density to protect against gouging, abrasion and mechanical stress.

The newest addition to PPG’s Phenguard range, Phenguard 985, is a flexible coating that tolerates higher film thicknesses and can be applied in two or three coats, depending on the project.

Carboline, St. Louis, part of RMP International Inc., Medina, Ohio, offers various coatings for hulls, tanks, and topsides. Carboguard 635 VAR is a low-VOC, epoxy paint that was developed for use in U.S. locations with strict Ozone Transport Commission Phase 2 VOC restrictions. Carbomastic 15 and 615 are lamellar-aluminum pigmented surface-tolerant epoxy mastics used as primers or midcoats in fresh or salt water. The Carbozinc product line includes zinc-rich primers for corrosion resistance. For nonskid decks, Carboguard 1209 adds grit and glass flake. Carboguard 890 series formulas are solvent-free and can be applied during new construction or maintenance. Topcoat options include the Carbothane 133 hybrid urethane series and Carbothane 134, an acrylic-urethane suited for UV-heavy environments.

GREEN AND CLEAN

“Antifouling paint is our bread and butter,” said Andrew Brasseaux, key account manager at CMP Coatings Inc., Belle Chase, La., the U.S. arm of Chugoku Marine Paints Ltd., Tokyo. “We’re looking for new ideas and ways to produce paints that are friendly to the environment.”

The company, which has warehouses on both coasts of the United States and in Panama, focuses on paints that are free of copper and tin. Its most popular product in this country is Sea Grand Prix 660HS because it protects against fouling in the warm waters of the Gulf. It also makes biocide-free, silicone-based bottom paints for commercial use called Bioclean Plus, Bioclean Plus EX, and Bioclean HB.

“I think silicone is the way of the future, especially for the biocide-free side of things,” said Brasseaux. Bioclean Plus is an elastomer foul-release coating. Brasseaux said it can have idle periods where the vessel can sit for up to a month. As soon as the ship starts moving, any fouling slides off, leaving a smooth, efficient bottom coating.

The company’s CMP Map program allows customers to track fuel savings. “It lets them compare the fuel efficiency over the lifetime of the coating,” said Brasseaux. “It’s really a groundbreaking kind of thing.”

CMP also makes tank linings, engine-room coatings, and silicone-based finishes for propellers and running gear. Seajet Pellerclean includes an epoxy primer for extended protection and longer intervals between applications.

A FRESH START

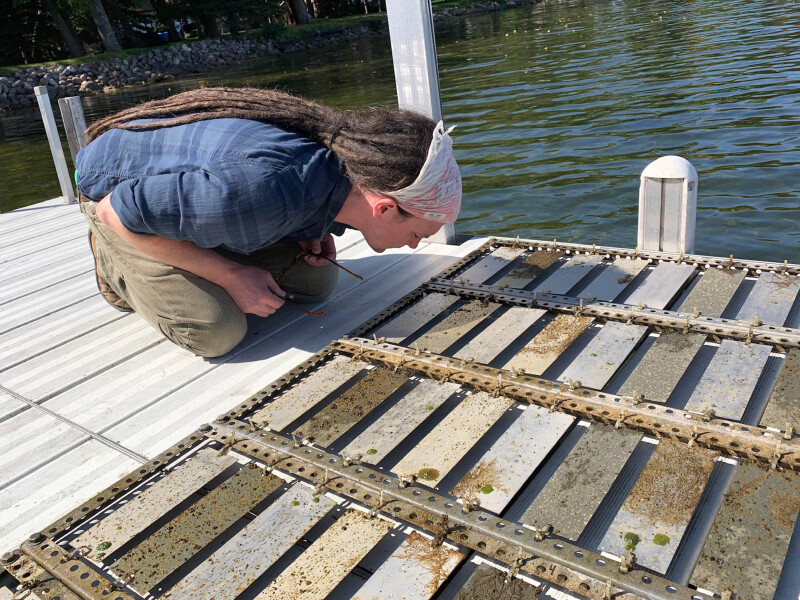

While most antifouling efforts focus on salt water, Elinor Coatings LLC, Fargo, N.D., specializes in freshwater protection. The company was founded by Dante Battocchi, CTO, part of a North Dakota State University research team, and his wife, Holly Anderson, CEO, in 2006.

Zebra mussels were first discovered in the Great Lakes in the 1980s, and by 2010, they had made it into the Mississippi River. “We started getting requests about freshwater fouling,” said Anderson. “We looked into it and realized there weren’t any companies focused on freshwater fouling.”

Elinor has been active in Department of Defense research, and in August, it opened a corrosion and weather testing facility in Fargo, with additional sites in Florida and Minnesota.

Its two key products are Aluma 45, a chromate-free primer, and Zebra Shield, a clear barrier coating developed to prevent zebra mussel attachment. Elinor is working on a polysiloxane topcoat that would be applied after the primer and then topped with the clear Zebra Shield.

“Our Zebra Shield coating is clear, which is nice for being able to see what’s happening underneath it with regard to corrosion,” said Anderson. “It’s durable and we’ve had it tested for specifications for three years before you had to recoat.”

Most tests have been done on aluminum, and the coating has passed the minimum tests for steel. The primer is sprayed in two coats, followed by a two-layer topcoat. Zebra Shield is a single layer. Because Aluma 45 is thinner and applied in two coats, the metal-rich coating covers more than thicker, competitive coatings, said Anderson. “It’s like spraying an anode on your whole boat,” she added.

The marine industry isn’t always one to embrace change. “We’ve seen practitioners at the workboat shows,” said Anderson. “They are wary of alternatives to the old standbys because the chromate works and the copper works… It only takes one or two to have a good experience with the coating and word of mouth will help it spread.”