Electrified shipping is gaining traction globally. By 2030, electrified ferries, tugboats, and cargo ships are expected to be valued at $14.2 billion. Provided electric propulsion increases in popularity, the importance of energy storage and battery logistics is top of mind for energy production companies.

According to a 2022 study focused on energy storage, various lithium-ion battery chemistries are available, with sources pointing at lithium manganese cobalt oxide as the most feasible solution for vessels. As the demand for electrified vessels continues to grow, so does the need for a sustainable and reliable supply of lithium.

The world’s first fully electric autonomous cargo vessel was launched in Norway in 2021. The 80-meter (262.4'), 3200-ton ship is powered by eight lithium-ion batteries with a capacity of 6.8 MWh, drawn almost exclusively by hydropower generation.

A key issue with electric propulsion is the lack of charging infrastructure. Though energy storage companies like Stemmann-Technik are addressing the issue, dockside charging facilities are still rare in ports. But this hurdle makes way for a new method of charging: power buoys.

Power buoys that are planned for charging at offshore wind sites could also be adapted to anchorage applications. The option could provide shore power while vessels await an available berth or next voyage instructions.

Supercapacitors and superconductors are energy storage technologies that are at varying degrees of development and commercial deployment in maritime.

Though these technologies are not yet in use on vessels, they are being pursued as an alternative energy storage source for specialized use based on the characteristics that differentiate them from batteries. Supercapacitor energy storage isn’t well-suited for primary energy storage on a vessel, though it can be found useful as a peak demand supplement, engine start, or dynamic positioning supplement.

HYBRID

Hybrid systems can be separated into two configurations: series hybrid or parallel hybrid. Series and parallel drivetrains enable the engine and electric motor to provide power independently or in conjunction with one another.

Series hybrid systems resemble diesel-hybrid propulsion, but they are paired with energy storage. Propellers are driven entirely by electric motors while diesel generators provide both propulsion and auxiliary power. The battery bank can be charged by a diesel-driven generator, shore power, or other natural energy sources such as wind, solar, and hydro. These batteries are charged during times of low power demand and discharged during peak power demand.

Parallel hybrid systems are a cross between conventional propulsion and a diesel-electric system. Parallel hybrid systems are best suited for vessels utilizing a range of propulsion power demands. Ideal candidates are harbor-assist and escort tugs that typically require high-power diesel engines driving large-diameter propellers. While assisting with the movement or breaking of oceangoing vessels, peak power is only needed during a small percentage of the vessel’s operating time while the remaining operations are spent idling or at low power.

Hybrid mechanical-electrical systems are growing in popularity worldwide. In 2018, Norway delivered a diesel-electric hybrid catamaran, Vision of the Fjords, that can operate on 100% battery power.

Washington State Ferries (WSF), the largest ferry system in the U.S., is currently converting 16 ferries to hybrid mechanical-electrical systems. The program has received $1.33 billion from grants and state and federal funding to date, though it still needs an additional $2.37 billion to be fully funded.

Maersk is piloting a 600-kW marine battery system on board the Maersk Cape Town, a 250-meter (820') container ship with a 4,500 TEU carrying capacity, to improve vessel performance and reliability. This vessel also includes a waste heat recovery system, allowing battery charging from waste heat.

BATTERY (ALL ELECTRIC)

Lithium-ion batteries are the most popular power source of all-electric vessels. Their high energy and power density paired with their relatively long life cycle makes them ideal candidates for marine transportation.

There are three primary Lithium-ion battery chemistries, each with its own set of preferred characteristics. They are nickel-manganese-cobalt (NMC), lithium-iron-phosphate (LFP), and lithium-titanate-oxide (LTO).

The NMC battery chemistry comprises the majority of today’s electric fleet, and it contains the highest specific energy of all three compositions. The desirable features of the additional two chemistries are an extended life cycle and increased stability, though each have lower specific energies.

In Gee’s Bend, Ala., the Gee’s Bend Ferry was retrofitted to 100% lithium-ion battery repower. The ferry runs on two banks of 135 kWh batteries and new 480 VAC induction motors for propulsion.

When vessels are operating over long distances, key challenges to using battery electric propulsion are time under power and the capacity to recharge. As a result, the amount of energy that can be stored by onboard batteries is limited. There are a few companies that are tackling this problem for long-transport vessels.

Asea Brown Boveri, EST-Floattech and Fleetzero have each developed containerized battery systems that are ruggedized for inversion, shock, and g-forces experienced onboard a vessel.

Last year, FleetZero secured $15.5 million and is in search of a vessel to convert to run on its container batteries. The company’s plan is to segment shipping routes into shortened trips, focusing on smaller ports and utilizing a battery-sharing scheme.

CHARGING STATIONS

Vessels operating on shorter, fixed routes, such as ferries and tugboats are optimal for electric operation. These routes can simplify charging infrastructure needs compared to larger cargo ships. Battery packs can fully power ferries for the duration of their journey, and predictable routes allow for efficient deployment of shoreline charging infrastructure.

German-based Stemmann-Technik is an energy storage company designing onshore power supply systems for container vessels and ferries. The systems are designed to withstand tidal changes and vessel movement.

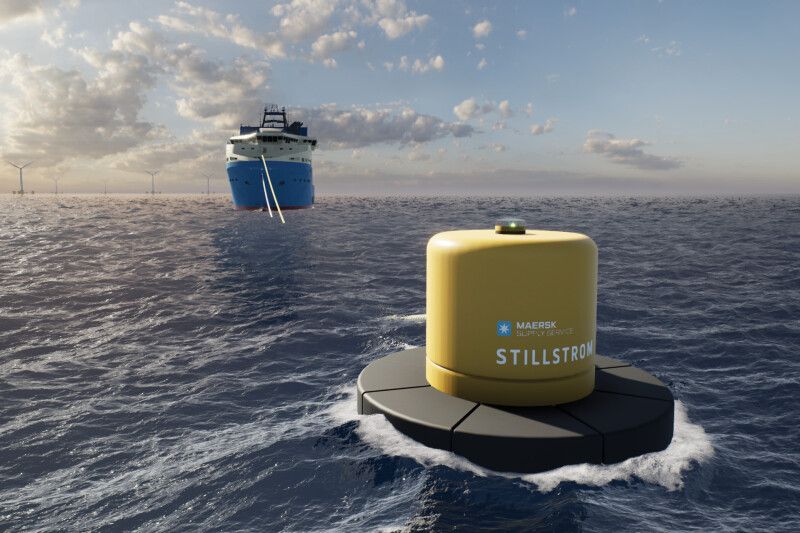

Another charging option that intends to facilitate traffic congestion in ports is offshore charging buoys. Maersk Supply Service and Ørsted have joined forces to test a charging pilot buoy in 2023. The trial will take place at one of Ørsted’s wind farms in the North Sea, with the Stillstrom prototype buoy supplying power to the service operation vessels (SOVs) and crew transfer vessels (CTVs) operating at the farm.

Charging buoys allow for cold ironing while at anchor. The overall reduction in emissions depends on whether the buoy-provided power is sourced from renewable inputs such as wind or hydroelectricity.

EMERGING ENERGY STORAGE TECHNOLOGIES

An emerging energy storage technology not yet commercially deployed is superconducting magnetic energy storage (SMES). Initially envisioned for load-leveling and shore-side, grid-scale systems, SMES is now being considered for pulsed power and peak shaving onboard vessels.

SMES consists of a superconducting coil that is cooled to a cryogenic temperature which allows it to reach a superconducting state. The operation of SMES is based on the notion that an electric current will continue an indefinite flow through a closed-loop system conducting electricity in any state of charge.

When charging, the current flows in only one direction and the power conditioning system generates a positive voltage across the coil to store energy. During discharge, the power conditioning system is modified to mimic the system as a load across the coil by generating a reverse voltage.

SMES systems are capable of quick response. In a matter of seconds, they can change modes from charge to discharge and vice versa, making them great candidates for pulsed power and peak-shaving onboard vessels.

Supercapacitors contain the same level of quickness when switching between the charge and discharge phases and they are on the verge of hitting the maritime market. Supercapacitors store electricity in the form of electrostatic energy, as opposed to batteries which store energy through related electrochemical reactions.

Nidec Industrial Solutions (NIS) is working with designers and naval architects to implement fast-charging supercapacitors for an all-electric ferry in France. Nidec's system will rely on 128 supercapacitors that will be distributed throughout each hull of the catamaran. Instead of the traditional battery recharging system which takes over 30 minutes to charge, it is projected that Nidec's supercapacitors will allow for the ferry to recharge in just 4 minutes.

German-based Skeleton Technologies is developing a supercapacitor module that’s undergone both air and liquid cooling tests and is undergoing a marine certification process.

There are limitations, however, in the total amount of energy that supercapacitors can store. That stored energy also self-discharges when it is stored for extended periods of time.

Overall, a vessel’s operational needs will dictate its specialized energy storage system. As electrification and alternative propulsion systems further establish their presence in the maritime industry, over time, one can expect energy storage systems will continue to advance categorically as they relate to vessel type.