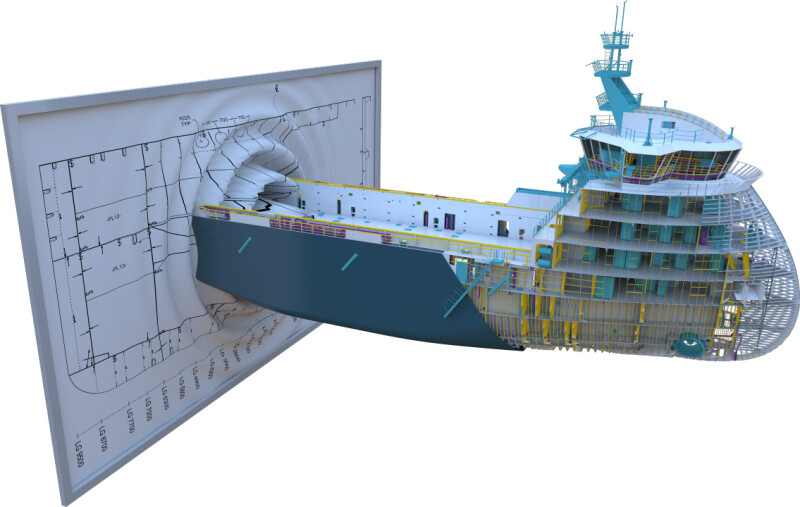

In recent years, shipbuilding design software has evolved towards integrated solutions that streamline the entire shipbuilding lifecycle. This includes design, engineering, manufacturing, and project management functions.

Integrated software allows seamless information flow between departments, enabling better collaboration, improved data accuracy, and increased overall efficiency.

Today’s ships are equipped with advanced technology recorders, sensors, and monitors, all providing real-time data collection and processing while harnessing the power of IoT services.

Artificial intelligence and automation are beginning to redefine the global maritime industry, launching autonomous ships and revolutionizing ship design and operations. These developments are driven by the need to make shipping safer, cheaper, and more sustainable.

Advancements in shipbuilding technology have also allowed for a quicker optimization of complex design problems, inevitably lessening capital expenditures. Naval architects and shipyards are now able to harness this design technology, producing numerous iterations of vessel design and quickly revealing how a minor alteration in design will impact vessel performance.

NEXT GEN TECH

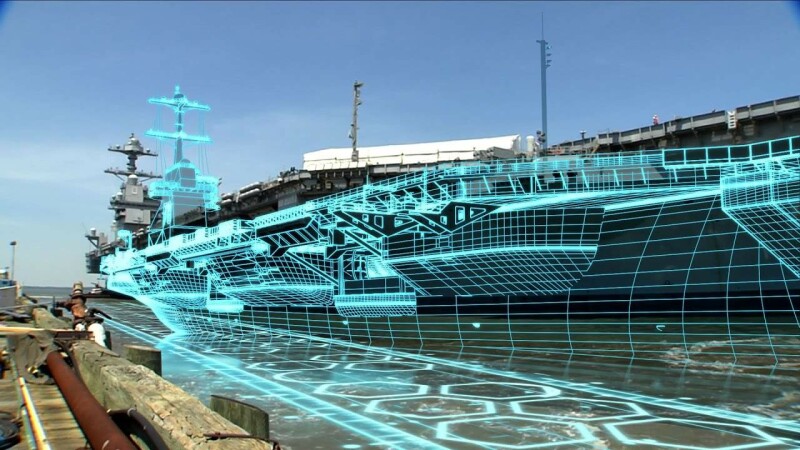

The latest frontier in shipbuilding design software involves the integration of virtual reality (VR) and augmented reality (AR) technologies. VR and AR enable designers, engineers, and stakeholders to experience ship designs in immersive virtual environments. They provide realistic simulations of vessel interiors, test maintenance scenarios, and aid in training and safety procedures. VR and AR technologies are further advancing the shipbuilding industry by enhancing design visualization, improving communication, and reducing errors.

Groupe Beneteau, an industry leader specializing in custom-built yachts, uses TechViz 3D visualization software in their design phases. The VR collaboration software allows their engineers to simultaneously work on the same project from different areas of the globe with military grade data security.

“Each user can see a 3D avatar of other users in a virtual environment and can point out changes, advantages, or flaws, directly on the same 3D model, in real-time. The only thing exchanged are the coordinates and actions of the users, so the model can’t be leaked or hacked out of the VR collaboration session," according to TechViz.

A big advancement in shipbuilding design software is the concept of digital twins and simulation. A digital twin is a virtual replica of a physical ship, utilizing real-time data and simulation models to monitor, predict, and optimize vessel performance throughout its operational life. Ship designers and operators can simulate and analyze various operational conditions, assess fuel efficiency, and identify maintenance requirements, leading to more sustainable and cost-effective operations.

VESSEL DESIGN SOFTWARE

Siemens offers various integrated design software solutions for shipbuilding. Its NX software is a comprehensive CAD platform, engineering analysis, and manufacturing planning tool. Siemens sid NX provides tools and functionalities to support the entire shipbuilding process, from initial design and concept development to detailed engineering and production. In the platform, shipbuilders can create 3D models of ships, perform structural and fluid dynamics analyses, optimize designs for performance and efficiency, and generate production-ready documentation. The software enables collaboration among different teams and disciplines involved in shipbuilding, facilitating efficient workflows, and reducing errors.

A case study from a Siemens white paper evaluated 500 designs of an MRV (multirole vessel) in under four days. It took approximately two hours of computing time per design (computer time, not person-hours). "Once the initial setup has been done the process is driven automatically by HEEDS (Siemens design space exploration and optimization software), working within the design constraints specified by the naval architect," the Siemens white paper said. "This automated, simulation-driven approach frees up naval architects to work on designs and insights rather than manually setting up and running simulations.”

Siemens also offers other software solutions tailored for specific shipbuilding tasks, such as Simcenter for simulation and testing, Teamcenter for data management and collaboration, and Tecnomatix for digital manufacturing and production planning.

Below is a brief overview of other available vessel design software:

· Dassault Systems 3DEXPERIENCE: This software suite offers a range of applications for ship design and engineering, including CATIA for 3D modeling, SIMULIA for simulation and analysis, and ENOVIA for collaboration and data management.

· SSI ShipConstructor: ShipConstructor is a CAD/CAM software specifically designed for shipbuilding. It provides tools for 3D modeling, structural design, outfitting, and production planning.

· AutoCAD Ship Design: Autodesk's AutoCAD software, widely used in various industries, has specific features and plugins for ship design. It allows designers to create 2D and 3D models, perform analysis, and generate documentation.

· Aveva Marine: Aveva Marine is a comprehensive software suite that covers the entire ship design and engineering process. It includes applications for hull design, outfitting, electrical systems, and production planning.

· Maxsurf: Maxsurf is a popular software package for naval architects and ship designers. It focuses on hull design and hydrostatic analysis, enabling the creation of optimized hull forms and hydrostatic calculations.

· C-Job Naval Architects: ACD resistance module is a user-friendly interface that optimizes hull design.

Each software has its own features, capabilities, and areas of specialization, thus it's important to research and evaluate different options.

As shipbuilding embraces digital engineering, the collaboration between software developers, naval architects, engineers, and shipbuilders becomes even more important.

This cross-generational collaboration was mentioned by Michael Fabey, a reporter and the author of "Heavy Metal: The Hard Days and Nights of the Shipyard Workers who Build America's Supercarriers," a 2022 book about Newport News Shipbuilding workers during the building of the USS John F. Kennedy. “The yard has been able to embrace technological advancements, not only with stuff that goes on the carrier but also how you build the carrier," Fabey wrote. "These young guys come in with their digital shipbuilding tools, and they work with these older shipbuilders in a way that meshes really well. They haven’t been replacing jobs, they’ve been augmenting jobs. The marrying of the old to new is exciting to watch.”

The evolution of shipbuilding design software has provided numerous improvements, ranging from increased efficiency and productivity to improved safety and sustainability. With further advancements on the horizon, such as artificial intelligence and machine learning integration, the future of shipbuilding design software looks promising.