Extensive Manufacturing and Repair in the USA Since 1981 - Fire Fighting Boats Equipped with Hunger Special Hydraulic Cylinders Examples of Application

Hunger hydraulic cylinders, telescopic cylinders and control systems have been used for mobile fire fighting on ships and in vehicles for many years. Special construction solutions as well as the highest production quality warrant their long life; also in offshore applications high reliability in critical applications is a given.

mobile fire fighting on ships and in vehicles for many years. Special construction solutions as well as the highest production quality warrant their long life; also in offshore applications high reliability in critical applications is a given.

Standard cylinders are self guided, anti rotation fire fighting cylinders with integrated feed of water and extinguishing agent as well as electrical lines for the monitor remote control.

Some excellent features of the Hunger fire fighting cylinders are compact in construction without additional feed or stabilizing equipment needed, anti rotation systems with extreme loading capacity and exactness over the entire stroke, a piston rod coating with a lasting corrosion resistance, and the Hunger DFE sealing and bearing combination for a stick and slip free movement and sealing without leakage.

Our multiple-stage telescopic fire fighting cylinders are an optimum solution for limited installation spaces without cutbacks in the required stroke

height of the monitor. Above all absolute function and operational safety over the planned service life are of decisive importance besides the technical design parameters such as quantity of flow, forward travel, stroke height, or angle of roll I acceleration of roll, attached man platforms if required are avaliable also!

Besides part of our scope of work are associated hydraulic power packs, installed cable drums as well as the control and control elements besides the fire fighting cylinders. Of course, we support you while choosing a fire fighting monitor or we can supply you with monitors of renowned manufacturers ready to fit to a fire fighting cylinder.

Hunger fire fighting cylinders facilitate a specific fire fighting ability of the fire by their versatility. The fire fighting cylinders can also be stationary and integrated in vehicles, or on offshore platforms, in power plants and chemical plants besides the application on fire fighting boats. The remote control of the fire fighting monitors as well as the telescopic cylinders enable an effective fire fighting also from a safe distance.

versatility. The fire fighting cylinders can also be stationary and integrated in vehicles, or on offshore platforms, in power plants and chemical plants besides the application on fire fighting boats. The remote control of the fire fighting monitors as well as the telescopic cylinders enable an effective fire fighting also from a safe distance.

Fire Fighting Boats Equipped with Hunger Special Hydraulic Cylinders Examples of Application

Always on guard, the 92-foot fireboat Victor L. Schlaeger, staffed by a dedicated crew, has faithfully protected Chicago for decades. Stationed between Navy Pier and the city’s water filtration plant, the Schlaeger, constructed in 1949, has been the cornerstone of the Chicago Fire Department’s marine firefighting efforts.

However, firefighting technology has remained largely unchanged for over six decades, and the city now requires more than just a fireboat—it needs a versatile rescue platform. To meet this need, the Chicago Fire Department turned to Robert Allan Ltd., a design firm based in Vancouver, B.C., to create a modern replacement. The new vessel had to meet current fireboat standards while navigating the unique challenges of Lake Michigan, including ice, low bridges, and shallow waters.

The result is a uniquely designed firefighting vessel, launched in April and delivered in early summer of 2011. Named the Christopher Wheatley in honor of a Chicago firefighter who died in the line of duty last year, the boat was built by Hike Metal Products in Wheatley, Ontario (the shared name being a coincidence). This vessel is one of several fireboats constructed in Canada for U.S. cities under a free trade agreement that expanded market opportunities for Canadian shipyards.

Robert Allan Ltd., renowned for its cutting-edge tugs and specialty vessels, faced a complex challenge with the Christopher Wheatley. “The vessel was engineered for year-round operation in Lake Michigan, the Chicago River, and nearby harbors, including conditions with up to one inch of first-year ice,” the design team explained.

Balancing a shallow draft with the constraints of low bridges was a significant hurdle, particularly in managing the vessel’s weight. Too heavy, and it risked grounding in the shallow river; too light, and it could collide with the low bridges spanning the Chicago River through the city’s downtown.

Dave Hewstone, a project manager at Hike Metal Products, noted that the hull’s spoon-like shape, nearly identical at the bow and stern, was designed to handle ice and shallow waters. Extra steel plating was added above and below the waterline to reinforce the hull, and robust skegs were included fore and aft to break ice and enhance directional control. With a draft just over 7 feet, the vessel’s depth can be adjusted using water ballast as needed.

Unlike the Schlaeger, the Wheatley operates as a “day boat” without crew quarters, allowing space for a dedicated EMS area accessible from the main deck, additional EMS space below, and a decontamination shower. The aft deckhouse, constructed from aluminum like the pilothouse, stores life rafts, life jackets, scuba gear, SCBA equipment, hoses, and other tools, accessible via large roll-up doors on both sides of the vessel.

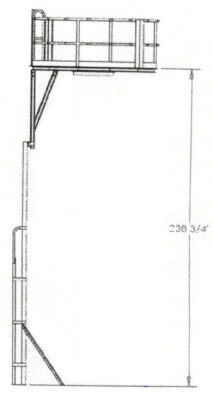

The firefighting system features four Stang monitors: a 6,000-gallon-per-minute unit at the center forward, two 3,000-gpm units on the forward port and starboard, and a 3,000-gpm monitor aft, mounted on a hydraulic mast built by Hunger Hydraulics in Rossford, Ohio, which can elevate the monitor 30 feet above the waterline. The vessel also includes nine hose manifold connections on both the port and starboard sides and four additional connections forward, enhancing its firefighting capabilities.

Technical Description for Fire Boat

Hunger fire fighting cylinders distinguish themselves by engineering particulars guaranteeing an optimum adaptation to the respective application. The port for the extinguishing agent feed is axially located in the cylinder rear end, the oil-hydraulic ports are mounted radial at the cylinder cap. The position of the cable drum is mounted laterally and may vary in broad ranges.

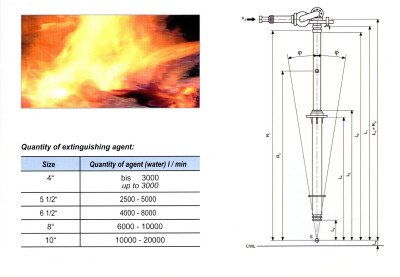

The fire fighting hydraulic cylinder can be designed in five staged sizes or as one, two or three staged hydraulic cylinder. With that stroke heights of up to 15 m with a flow rate of the extinguishing agent of up to 20.000 I/min can be covered. Besides the fully integrated extinguishing agent and cable feed, the anti rotation protection is effective over the entire stroke allowing the extinguishing operation in any position. Besides engineered solutions for electrically operated extinguishing monitors, we also offer, upon request by the customer, solutions for the mounting of manually or hydraulically operated extinguishing monitors.

The fire fighting monitors are designed and built in such a way that they are integrated as pre-mounted unit into the structure of the fire fighting boat or the extinguishing vehicle. The connection is achieved by flange mounting areas for the mechanical, the oil- hydraulic, and the water-hydraulic as well as by a wire box for electrical cables.

The stabilitization is the most important design element besides the determination of size and stroke of the fire fighting cylinder. For fire fighting boats, the mathmatical stability proof is done according to “DNV - Rules for Ships; January 2003, Pt. 3, Ch. 1” as well as the rules of the “Germanischen Lloyd” for safety factors and design regulations.

Among others, the following factors are included in the mathmatical stability proof:

- Height of the extended extinguishing monitor

- Angle of roll of the ship (side deflection)

- Acceleration of roll of the ship

- Position of centre of gravity of the ship

- jet reaction of the extinguishing monitor

Materials complying with the high stability requirements of ship building as well as requirements for corrosion and wear resistance by optimized surface coating procedures and special bonding technologies for stainless stee1 and carbon steel.

Both the construction and the engineered design of a fire fighting cylinder are tested and approved in each case by the appropriate authority.

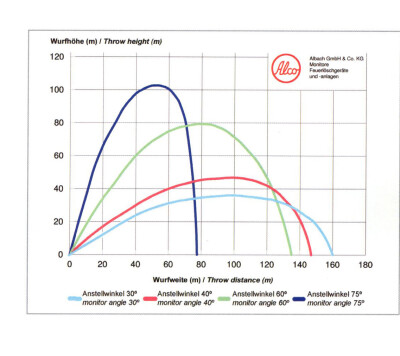

The design of the fire fighting monitor depends on multiple variables: the required flow rate of the extinguishing agent, the available pressure of the extinguishing pump, throwing range, type of extinguishing agent or extinguishing agent additives and types of operation.

The design and the supply of the extinguishing monitor can be done by our customer or by us. With pleasure, we submit an offer to you based on well known manufacturers of extinguishing monitors and accessories.