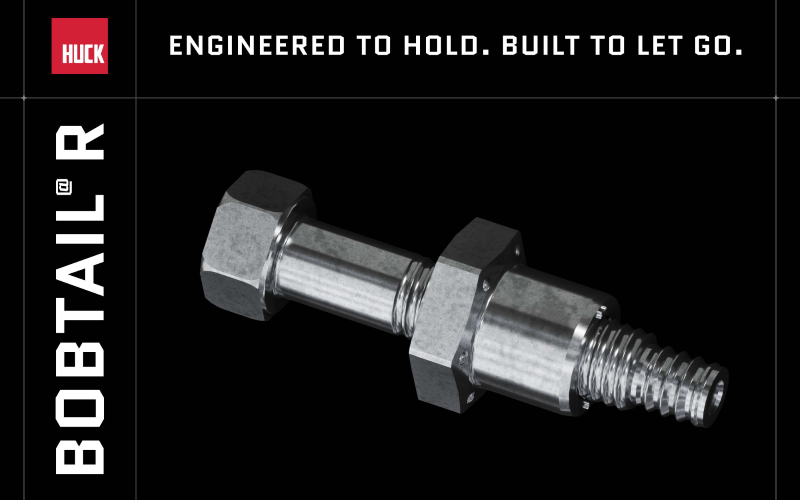

Revolutionary Permanent Fastener Offers Unmatched Vibration Resistance — Yet Removes Easily with Standard Torque Tools

.png.small.400x400.png)

FOR IMMEDIATE RELEASE

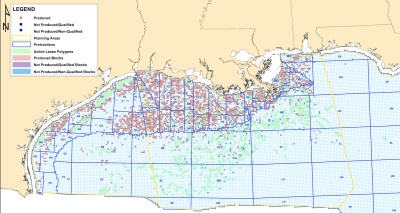

[Waco, Texas] — [February 10, 2026] — Howmet Aerospace, a global provider of engineered solutions for aerospace and transportation industries, proudly announces the launch of its Huck® Bobtail® R fastener, a breakthrough in fastening technology that delivers all the permanence of a traditional lockbolt but can be easily removed using traditional torque-type tools.

Engineers have long faced a key trade-off in joint design: permanence or serviceability. Huck® Bobtail® R eliminates the need to compromise. The latest iteration of the original lockbolt, Bobtail® R delivers a robust, vibration-resistant hold that can be removed quickly and efficiently without specialized equipment. And unlike traditional joining methods like threaded fasteners and welding, Bobtail® R installs with intuitive tooling that addresses the skills gap facing manufacturers the world over.

"We designed Bobtail R to bring the immense value of Huck® lockbolts to a wider audience," said Jonathan Craven, Engineering and Technology Director at Howmet Aerospace. "Bobtail® R is as permanent as any Huck® lockbolt with the added value that, should it need to be removed, it can be – safely and with conventional tools."

Key Features and Benefits:

- Reduced Maintenance — Eliminates fasteners that loosen under stress and vibration to reduce maintenance costs and warranty issues.

- Reduced Training Time – Intuitive installation equipment simplifies metal joining and reduces training time.

- Improved Strength – Consistent, repeatable installation ensures strong, secure joints with up to five times the fatigue strength of a traditional bolt.

- Easy Removal Without Special Tools — Compatible with standard torque wrenches and drivers, allowing for field serviceability without special equipment.

Applications Across Industries

Bobtail® R is ideal for all assemblies where safety, reliability, and serviceability are equally critical. In marine applications, it provides a secure, maintenance-free hold for critical joints while being fully serviceable when required. For heavy machinery, its easy removal means repairs can be performed onsite, without requiring special repair facilities. Support vehicles and structures can be modified and upfitted to the same standard of permanence as the rest of the structure.

"This is more than just a fastener — it’s a productivity tool," added Craven. “Still maintenance free, still with unmatched preload consistency, still vibration resistant, and installed with the same simplicity and reliability as traditional Huck® lockbolts."

Availability

The Huck® Bobtail® R Fastener is now available in a variety of diameters and coatings to suit a wide range of applications. Custom configurations can be developed for specialized needs.

For detailed specifications, pricing, or to request a sample kit, visit www.hfsindustrial.com or contact Ambryn Hengst, Associate Product Manager, [email protected].

About Howmet Aerospace

Headquartered in Pittsburgh, PA, Howmet Aerospace, Inc. holds the number one global position in aerospace fastening systems and is the North American leader in commercial transportation fasteners. Our industrial products are critical components of industrial gas turbines, automobiles, commercial transportation vehicles, and construction and industrial equipment.

Behind every Howmet Fastening Systems product is a commitment to bringing users the strongest, most reliable fastening solution available – regardless of industry. Our uncompromising approach to engineering, manufacturing quality, and breadth and depth of products is unmatched – resulting in a range of structurally superior fasteners and ergonomically designed installation tools.

Media Contact:

Michelle Hanley

Marketing & Product Manager

[email protected]

254-751-3057