Chevron Corp. announced this week it has sanctioned the Anchor project in the U.S. Gulf of Mexico. This marks the industry’s first deepwater high-pressure development to achieve a final investment decision. Delivery of the new technology, which is capable of handling pressures of 20,000 psi, also enables access to other high-pressure resource opportunities across the Gulf of Mexico for Chevron and the industry.

“This decision reinforces Chevron’s commitment to the deepwater asset class,” Jay Johnson, executive vice president, upstream, for Chevron said in a statement announcing the project go ahead. “We expect to continue creating value for shareholders by delivering stand-alone development projects and sub-sea tie backs at a competitive cost.”

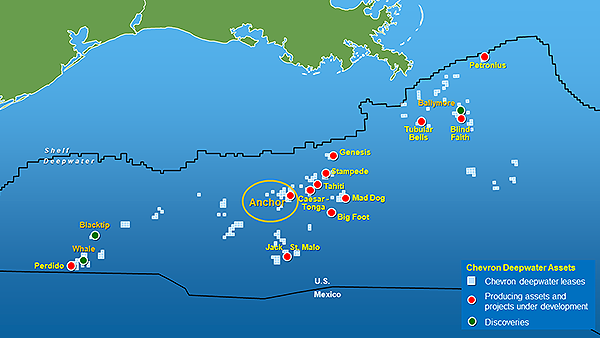

The Anchor Field is located in the Green Canyon area, approximately 140 miles (225 km) off the coast of Louisiana, in water depths of approximately 5,000' (1,524 m). The initial development of the project will require an investment of approximately $5.7 billion. Stage 1 of the Anchor development consists of a seven-well subsea development and semi-submersible floating production unit. First oil is anticipated in 2024.

The planned facility has a design capacity of 75,000 bbls. of crude oil and 28 million cu. ft. of natural gas per day. The total potentially recoverable oil-equivalent resources for Anchor are estimated to exceed 440 million bbls.

Chevron, through its subsidiary Chevron U.S.A. Inc., is operator and holds a 62.86 % working interest in the Anchor project. Co-owner Total E&P USA Inc. holds 37.14% working interest.

“For new projects in the Gulf of Mexico, we have reduced development costs by nearly a third, compared to our last generation of greenfield deepwater investments,” said Steve Green, president of Chevron North America exploration and production. “We’re doing this by standardizing equipment, utilizing fit-for-purpose surface facilities that require less capital and employing drill to fill strategies. At Anchor, we streamlined our front-end engineering and design phase and are utilizing more industry standards in our designs and equipment to lower costs while maintaining operational excellence.”