The U.S. Navy has expanded the use of additive manufacturing, also known as 3D printing, across frontline fleet operations, cutting production lead times by as much as 70%.

Through coordination among Naval Sea Systems Command (NAVSEA), the Maritime Industrial Base, and private industry, the Navy moved additive manufacturing from testing and evaluation into routine use within the supply chain in 2025. Officials said the effort improved fleet readiness and increased resilience in logistics and maintenance.

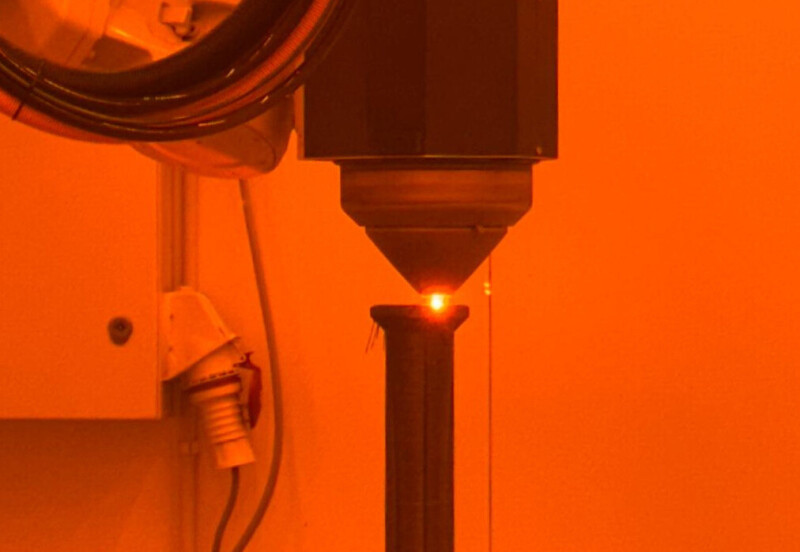

Among highlights, Huntington Ingalls Industries installed a 4'11"-long, 992-lb. additively manufactured metal valve manifold aboard a nuclear-powered aircraft carrier, marking the first installation of its kind on the platform. The submarine force also installed a metal, 3D-printed component on a Virginia-class submarine, which industry partners described as a “giant leap” for the subsurface domain, demonstrating the technology’s ability to meet deep-sea operational requirements.

International cooperation remained a central element of the Navy’s additive manufacturing strategy. In 2025, the United States, the United Kingdom, and Australia completed a shipboard installation of a metal, 3D-printed part under the AUKUS partnership, highlighting progress toward interoperable and interchangeable repair capabilities among allied navies.

The Navy reported immediate efficiency gains from the expanded use of additive manufacturing. In one case, industry partner Marotta reduced a traditional 29-week lead time by 70% for a critical valve used on Navy destroyers by using metal 3D printing and avoiding conventional manufacturing bottlenecks. At Navy maintenance centers, the use of additive manufacturing for ship repairs resulted in cost and schedule savings, including more than $300,000 in cost avoidance from a single polymer component developed by the Southeast Regional Maintenance Center.

Additive manufacturing also supported joint-service operations. The Navy partnered with the U.S. Coast Guard to restore equipment on a Coast Guard vessel using a polymer 3D printer installed on an in-service submarine. The effort demonstrated the technology’s ability to support rapid, cross-service repairs.

NAVSEA officials said a structured, low-risk approach has enabled waterfront and forward-deployed maintainers to use additive manufacturing for real-time maintenance needs. At the Forward Deployed Regional Maintenance Center in Rota, Spain, repair times were reduced by 80% by fabricating a required part using additive manufacturing.

In parallel, NAVSEA collaborated with academia and industry to streamline material qualification processes, reducing testing requirements by more than 60% and saving millions of dollars in qualification costs. The command also released three additive material specifications—MIL-PRF-32802, MIL-PRF-32803, and MIL-PRF-32804—available through the ASSIST database.

NAVSEA said it will continue expanding additive manufacturing efforts in partnership with the fleet, industry, and academic institutions. Companies such as Hunt Valve are developing and certifying additional additively manufactured parts to broaden the range of components available for fleet use.

Navy officials said the progress achieved in 2025 reflects a shift in how additive manufacturing is viewed across the naval enterprise, with 3D printing now integrated into planning, maintenance, and sustainment as a tool to support fleet readiness and resilience.