Mike Hanna has worked for the Association of Maryland Pilots for 41 years. He began his career on the Maryland, a 200' oceangoing tug converted into a pilot boat, stationed off Cape Henry, Virginia Beach, Va., to assist pilots during their round trips along Chesapeake Bay. After the Maryland was retired, the association shifted to a shore-based operation, where Hanna started as a launch operator and eventually moved up to the pilot tower. He later became the Cape Henry station manager and, ultimately, the marine manager for the entire company. In this role, he oversees hiring, training, and the building and maintenance of pilot boats at all four of the association’s stations, spanning from Maryland to Virginia.

Hanna and his team of launch captains at the Cape Henry pilot station have developed a maintenance program that keeps boats built in the 1980s looking and running as well as they did the day they were delivered.

“Our goal is not to have any downtime,” said Hanna. “With our maintenance program we have reduced the downtime considerably, and it’s a lot less expensive to maintain [a boat] than it is to repair.”

The association’s fleet has 12 boats built by Gladding-Hearn Shipbuilding, Halmatic, and others. Hanna implemented the maintenance program on the three-boat fleet at Cape Henry because they operate in the most challenging conditions. He’s also part of an effort to form a pilot boat alliance under the umbrella of the American Pilots’ Association, where pilot boat captains can share information and give each other tips on how to maintain boats at a higher level to help reduce downtime.

“When you talk with some other groups, you realize there’s a lot more you can be doing,” said Hanna. “We had our first meeting of the pilot boat alliance at the International WorkBoat Show two years ago, and I learned that many are using the Sinex program.”

Vessel software from Sinex Solutions allows fleet owners to track boat repairs. Currently, the Association of Maryland Pilots has the records in three-ring binders.

“With the Sinex program, we can quantify anything we want,” Hanna explained. “I learned about it from the first pilots’ alliance meeting, and then we find out that right next door, the Virginia pilots are using it.”

FAMILIARITY BREEDS COMPETENCE

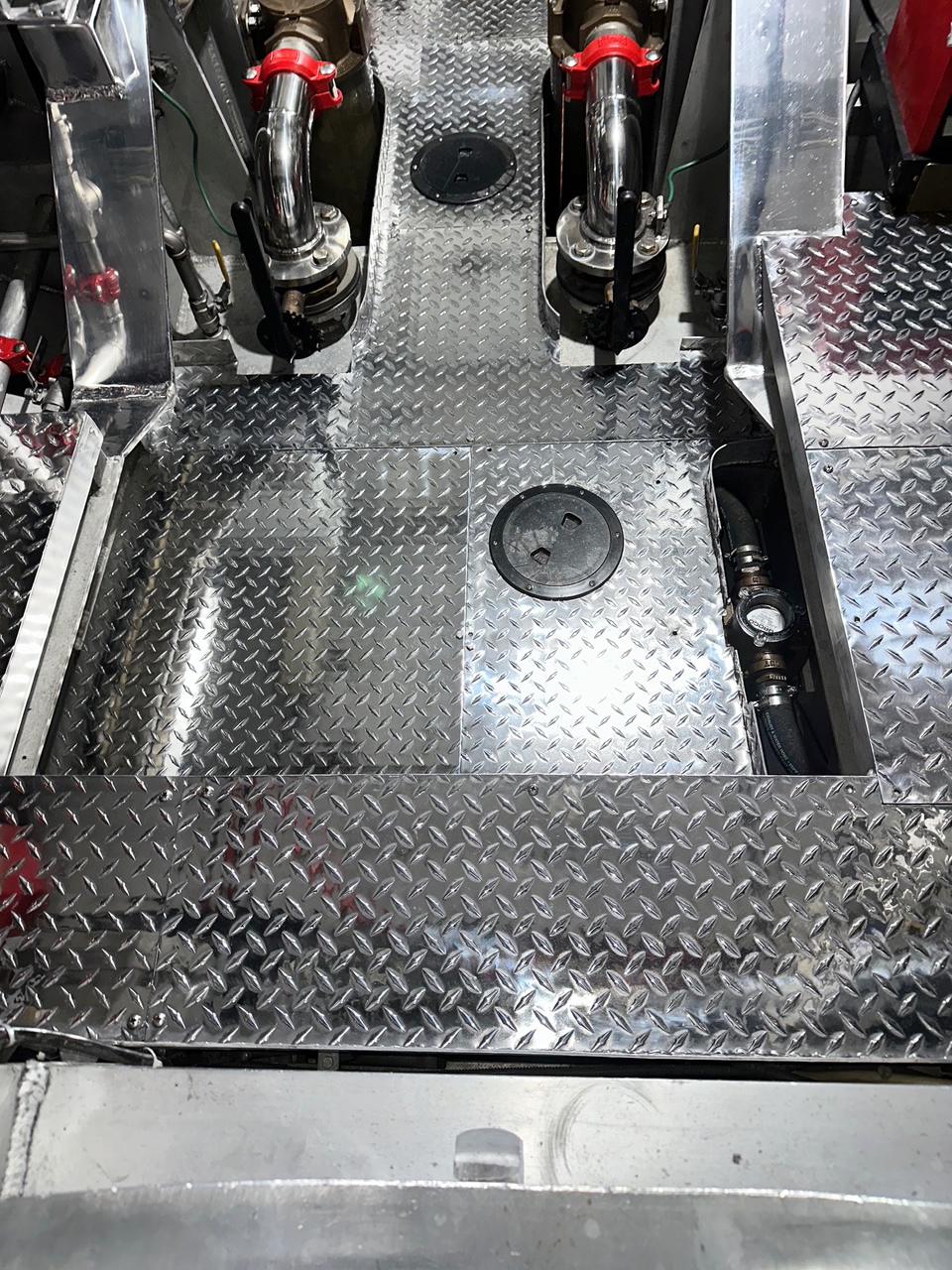

Common sense tells us that the more you know about a piece of equipment, the better equipped you’ll be to handle an issue when one pops up. “The more time our guys spend in the engine room, the more things they find and the more familiar they are with the systems and the operations of the boat,” said Hanna. After all, a clean bilge makes it easier to spot a leak.

While some ports have an engineer dedicated to vessel maintenance, Cape Henry does not. Instead, the launch captains have varying levels of technical skills, and those with more knowledge teach the others how to make repairs.

The captains work 12 hours on, 12 hours off for a week, with the following week off. There are four launch captains per watch, and they change shifts in pairs at 0400, 0500, 1600, and 1700. “During the shift change, we let them take it easy until 0800, and then everybody goes to work,” said Hanna.

At Cape Henry, there are three 53' Gladding-Hearn boats. The boats are rotated, with two in service and one being maintained, not repaired. “Typically now, it’s not that something’s wrong, it’s that boat’s turn to come in for maintenance,” said Hanna.

The launch captains have a checklist, similar to a pre-flight checklist for aircraft. The morning crew goes through it every day, and when the shift change takes place 12 hours later, incoming captains repeat the process.

Even for something as simple as replacing a light bulb, a damage report is filed so there’s a record. Hanna said that because the boats have been running continuously since the improved maintenance program was developed, the station has stopped tracking downtime. “We used to years ago, but we don’t even track it anymore,” he added. “We know we reduced both [cost and downtime], but I can’t put a real number on it.”

THE PROCESS

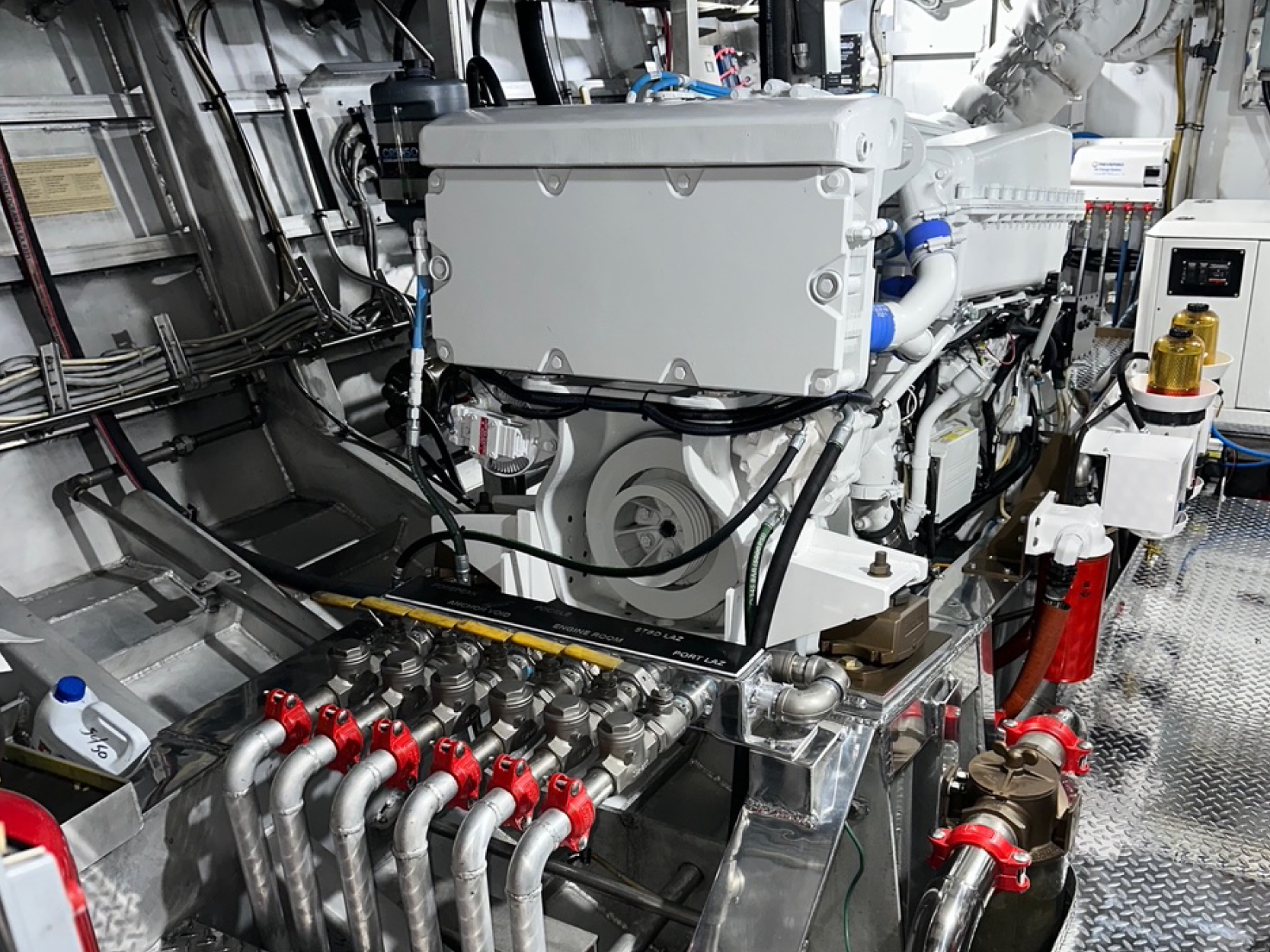

On each pilot boat, systems include propulsion, generators, heat and air conditioning, and electronics. Each launch captain has his or her own skillset, with one, for example, having a solid background in electronics. Most of the boats are powered by twin diesel inboards. When a major issue arises, the Cape Henry pilot station brings in Ayers Marine Electronics, Chesapeake, Va., for electronics, and Grand Slam Diesel Services, Virginia Beach, Va., and Western Branch Diesel, Portsmouth, Va., for engine work. Grand Slam has been working with the launch captains, teaching them how to rebuild diesel engines.

One launch captain, Jordan Peters, showed an interest in polishing and cleaning the aluminum Gladding-Hearn pilot boats, and that led to him tracking down a course in Texas on how to properly Cerakote the aluminum on the vessels to protect it.

After returning from the class, Peters started applying the protectant to all aluminum components on the boats, and he started his own company, Coastal Metal Polishing, in Virginia Beach, Va.

All of the Association of Maryland Pilots’ launch captains have been educated on how dissimilar metals interact and how the Cerakote protects. “The Cerakote process we have in place is really extending the life of our aluminum boats and certainly reducing any major hull repairs as a result of corrosion,” said Hanna.

A closer look at the nether reaches of the bilge revealed that the hull bottom was pitting beneath the bronze raw-water strainers. “Aluminum hulls rot from the inside out,” said Hanna. “We could see underneath those components that there was pitting on the aluminum. I’d rather pay my employees to have a highly maintained boat.”