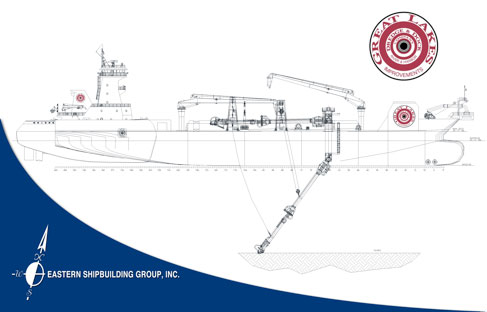

On Jan. 10, Great Lakes Dredge & Dock Company (GLDD) and Eastern Shipbuilding Group (ESG) signed a contract to build a new trailing suction hopper dredge ATB unit. The ATB will be made up of a 433'x92'x36' trailing suction hopper dredge barge and a 158'4"x52'x32'9", 15,600-bhp CPP tug. The ATB will be built at Eastern’s Panama City, Fla., facilities. The cost of the ATB will be approximately $140 million inclusive of equipment and materials GLDD has already purchased and will provide to the shipyard for installation.

In August 2012, GLDD entered into a contract with Signal International for $94 million for the design and construction of the ATB dredge. Construction was originally scheduled to begin in January 2013. However, in April 2013, Signal announced that work on the ATB unit had been discontinued at the request of GLDD.

In a quarterly earnings call, Jonathan Berger, CEO of GLDD, said the company was excited to be working with Eastern on the project. "The price has increased significantly from our initial expectations, but we are confident that the vessel will be the most efficient in industry and a true game changer. In addition we have successfully settled our dispute with the first shipyard we separated from and received a $10 million settlement."

Berger said he is confident the project will go well and be on time for a mid-2016 delivery.

Named the GLDD302 (ESG Hull 252), the ATB tug detailed engineering is being performed by Ship’s Architect. Engineering on GLDD151 (ESG Hull 253), the ATB dredge barge, will be performed by Bay Engineering. Both are the based upon an Ocean Tug & Barge Engineering ATB design.

The GLDD dredge will be a key tool in performing the restoration of the eroded land mass in the Gulf Coast States, the company said. Additionally, the vessel’s ability to cost-effectively deepen and maintain navigable waterways will bolster the United States’ competitive position in world trade, as the nation’s ports move forward with deepening plans to accommodate the larger vessels, which will sail through the expanded Panama Canal, according to GLDD.

The ATB dredge features the following characteristics:

GLDD302 ATB tug:

Dimensions (Overall): 158'4"x52'x32'9'

Horsepower: 15,662 bhp

ATB coupler system: (2) Taisei Coupler Systems

Main engines: (2) Mak 12M32C-T3, 7,831HP each

Main generators: (2) 2,500kW, 6600VAC Shaft Generators

Auxiliary generator: (1) Caterpillar C32-T3 730kW @ 1800rpm

Emergency generator: (1) Caterpillar C18-T3 550kW @ 1800rpm

Classification: ABS A1, AMS, ACCU, Oceans Towing Vessel Unlimited Service additional notations ILO, and certified under SOLAS/IMO/MARPOL

Flag and regulatory: USA, USCG Dual-Mode ITB, 33/46CFR

Subchapters, E, F, G, I, J, M, Q and S

GLDD151 ATB trailing suction hopper dredge barge:

Dimensions (Overall): 433'x92'x36'

Hopper capacity: 14,920 cu. yds.

Dredge system power: (2) EMD ME20G7C-T3, 5,000hp each

Bow thrusters: (2) Schottel STT2 Electric, Fixed Pitch Tunnel Units 800hp each

Harbor Service Genset: (1) Caterpillar C32-T3 910kW @ 1800rpm

Classification: ABS A1, AMS, Unmanned Cargo Barge and certified under SOLAS/IMO/MARPOL.

Flag and regulatory: USA, USCG, 33/46CFR NVIC Publications, Certificated “I” Unmanned.