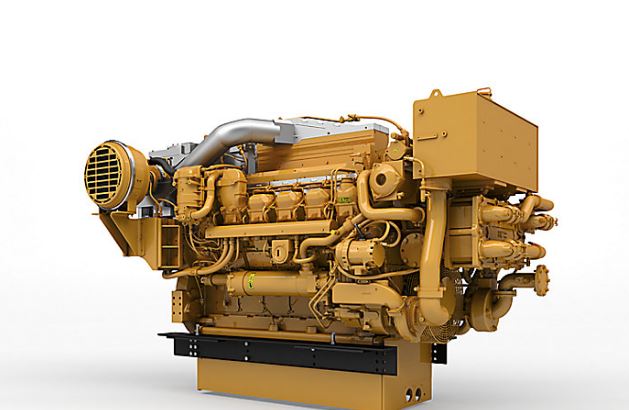

The U.S. Environmental Protection Agency’s Tier 4 diesel engine regulations have been met by the workboat industry with less than enthusiasm. The Tier 4 rating applies to engines above 804 hp and focuses on reducing two air emission elements: particulate matter by 90% and nitrogen oxide by 80% when compared to Tier 2 engines.

These engines should offer owners reduced emissions and improved fuel consumption, perhaps as much as 5% to 10%, but overall cost and loss of floor space have been among the concerns.

Caterpillar meets Tier 4 requirements by matching up a diesel engine with a selective catalytic reduction (SCR) aftertreatment system. That system uses urea that’s dosed into the exhaust stream and a catalyst to create a chemical reaction that removes oxides of nitrogen in the exhaust, leaving only nitrogen and water vapor.

The system requires a urea tank that is placed outside the engine room, because long periods of heat is an enemy of urea. Consequently, a system is needed to move the urea from the storage tank to the small urea tank on top of each engine.

Brad Del Rio with his pump transfer skid. Ken Hocke photo

A new company called DDR Flow Control, Gray, La., says the needed system is a pump transfer skid that pumps urea in the proper amounts and at the proper pressure.

“Basically, it pumps urea from a 500 gallon or more storage tank into four-gallon tanks located on the Caterpillar engines,” said Brad Del Rio, one of DDR’s co-owners, whose family business (The Del Rio Company) has sold back pressure regulators to chemical plants since 1971. “Cat dosing cabinets solenoid valve will not operate properly if the supply pressure is below 4.9 or above 9.9 psi. The Jordan valve pressure regulator we use provides the lowest spring droop on the market and controlled full open to full close within 1.5 psi during our test.”

Del Rio said he approached a long-standing customer and friend that was extremely experienced in flow and measurement controls — Paul Donovan. “After some creative discussions and a few meetings with people affiliated with Caterpillar engines, we formed DDR Flow Control. Our sole purpose so far is to build trust and alliances with marine engine manufacturers in order to provide them with a pump transfer skid they can rely on for compliance,” said Del Rio.

In late February, DDR introduced its skid to numerous naval architects, engine suppliers and towboat companies at its facility in Gray, La. DDR Flow Control photo

In late February, DDR introduced its skid to numerous naval architects, engine suppliers and towboat companies at its facility in Gray, “accompanied by a great Cajun meal,” he said. “It was a great turnout. People are interested in our skids. We’re tweaking them to meet ABS standards and customer needs, and we’re confident we have the right product because of our backgrounds in valve and pressure regulators and flow and measurement controls. Paul and I have been doing this our whole careers, and we think we have the product the marine industry needs.”

DDR will get its chance to prove itself next month when a new passenger vessel being built at Gulf Craft, Franklin, La., will be delivered using DDR’s pump transfer skid. “It’s really about controlling the pressures and controlling the flows,” said Del Rio. “And we can do multiple engines with one of our skids.”