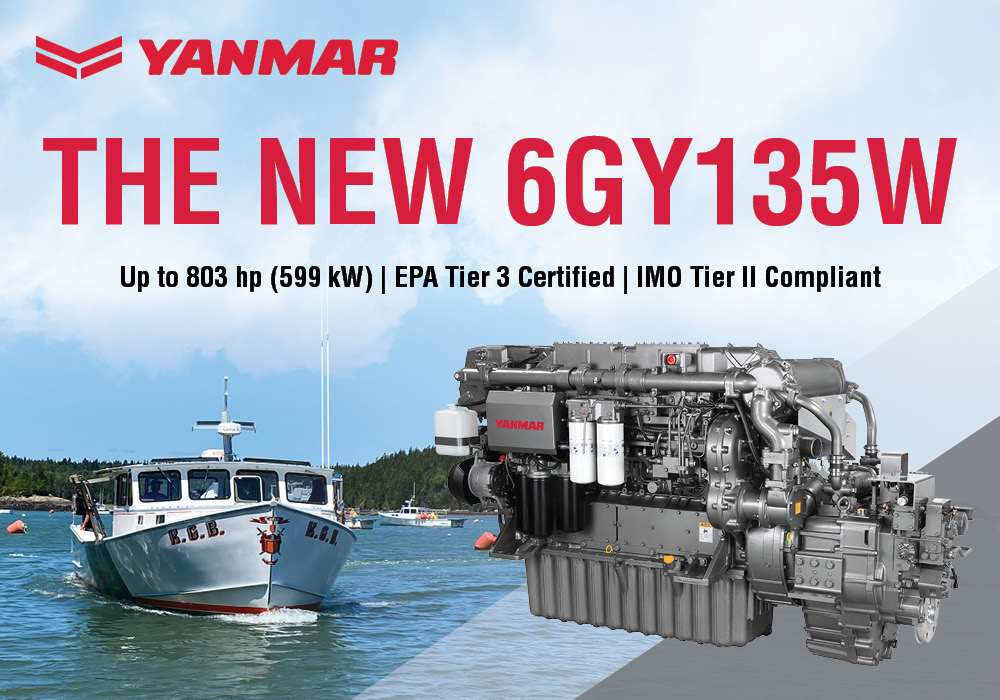

The maritime industry is no stranger to the challenges posed by emissions regulations, technological advancements, and the need for reliable performance. YANMAR commercial marine engines are designed and purpose-built to be used in marine applications, not the marinized versions of on/off road engines that can be found in product lines of other engine manufacturers. This approach leads to several benefits, including improved fuel economy, enhanced serviceability, and heightened reliability and durability. At this year’s International WorkBoat Show, YANMAR unveiled its new purpose-built marine engine, the 6GY135W.

WorkBoat spoke with Carl Micu, YANMAR's Division Manager of Power Solutions, to walk us through the engine firsthand. “We're competing in this range, the 14.6 liters, so you compete against the truck conversions. This is a complete marine-dedicated design,” said Micu. “With serviceability on larger engines, you have side plates, so you can change individual kits. This engine also has that. No other engine in this power range has that.”

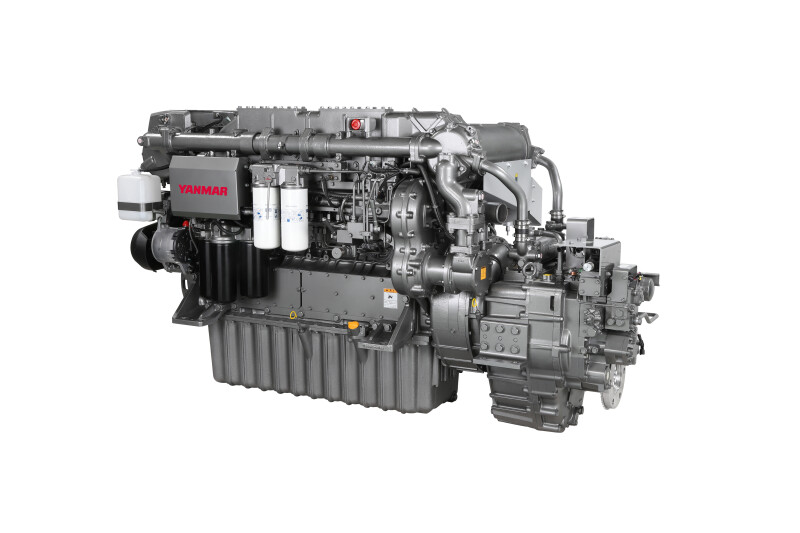

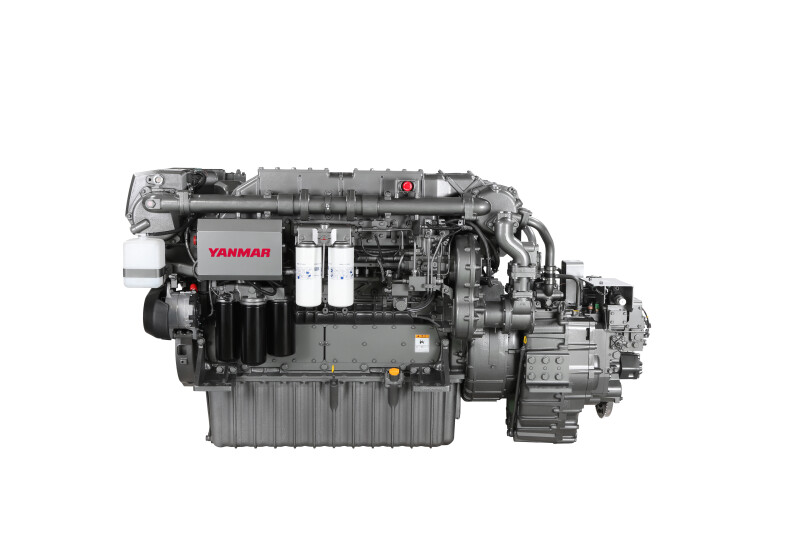

Serviceability was top of mind during the design process. The removable side panels on the 6GY135W allow for direct access to the connecting rods and crankshaft, which makes everything from routine maintenance to repairs simpler and quicker than ever before.

Nathan Stabile, a YANMAR marine engineer, emphasized the significance of collaborating with customers to enhance lifecycle performance and reduce operational costs. “I think that the lifecycle part is really a key thing for us. Working with customers upfront and talking to them about what that lifecycle is going to look like, and how we can help improve their bottom line and make sure that they're doing what they need to do. There's always maintenance, there's always service, there's always things that happen. But can we make the engine in such a way that those things are addressed faster. We've got parts available here in the country and keeping that ball rolling is key.”

Additionally, both representatives stated the multi-stage fuel injection pattern allows for the engine to operate quietly, reducing emissions by 80% with the common rail system.

YANMAR's YXH-160 gearbox, engineered and load-tested alongside the engine, ensures peak performance and reliability. The engine and gearbox are assembled with torsional coupling, oil cooler, mounts, cooling pipes, and companion flange included. The integration of electronic controls is also tailored for marine use, providing a torque curve specific to marine applications.

“The other part of it is electronic controls. Other engines have electronic controls too, but they're coming from a base engine on the truck market. What we're doing is developing that torque curve, and that power curve specific to what we know about marine, and we’re customizing that. So, we can have steeper torque with less drop off on the torque curve,” said Micu. “We met with a customer today. And he said, you know, the gear is so simple. It's bulletproof. If I need to do something to it, it's really easy to work on.”

Stabile emphasized the importance of understanding customer operations and tailoring services to their needs. YANMAR offers a one-stop service for both custom-made engines and matching marine gears.

With a focus on the 500 continuous horsepower rating in the 14.6-liter category, Stabile expressed YANMAR's excitement about the engine's potential in the tug and push boat market. “We're taking a look at where we compete and what power ranges and what engine displacements we compete against. We're looking at a 19-liter that we are beating on torque curve, and we're beating in power, and they’re almost identical on fuel consumption. So, it’s a 14.6 versus a 19-liter.”

When Stabile was asked what he was most excited about with this new engine, he noted, “I think for us here in the USA, it represents another power node and engine possibility for us to go after both in repower and in new builds. That 500 horsepower rating in this size, I just think is fantastic and we have an excellent torque curve. And we can line up with all of our competitors and show that on paper and we can feel that in the boats, as well. So, I think that's what I'm most excited about.”

As the industry shifts toward cleaner engine alternatives, YANMAR’s new 6GY series puts forward an environmentally friendly unit that doesn’t sacrifice on performance. The 6GY135W offers low emissions, low noise levels, precise fuel injection control, and high output torque, while its removable side panels make it the only engine in this power range to offer this level of serviceability.

Approximately 20 of these new engines are already operational in Japan, with commercial availability in the USA and Canada expected in late 2024.