Several safety items aboard are bypassed, disconnected, or just ignored whenever they are perceived as an annoyance. Most of the time the crew can get away with it, but not always.

You’ve investigated the high water alarm several times already and found that the float switch is just placed too low in the bilge. So you disconnect the alarm. The following night the bilge pump stops working, the water rises, and the crew must abandon ship as the vessel sinks. It does happen.

This next scenario is caused by environmental concerns. Environmental agencies are constantly on the alert for oil or gasoline discharges on water. The fines are extremely costly and vessel owners do not want to have to pay for these infractions.

Oils normally accumulate in the bilge along with water. If the boat has no oily water separator, or if a separator is full, the oily bilge water may be automatically pumped overboard if the level reaches the high-water float switch of the bilge pump.

There have been some instances of automatic bilge pumps being disabled or disconnected to prevent the oily water mix from the bilge being pumped overboard. It seems like a good quick fix, until the owner is informed that his vessel is at the bottom of a river leaking fuel and oil. As the vessel is raised from the bottom an inspection proves that the pumps were tampered with which then nullifies the insurance policy and the insurance claim.

Another annoying noise comes from the smoke detector. What a hassle it is to remove the battery just to have a smoke in your bunk and then you must put the battery back when you’re done. You may be done sooner than you expected — well done that is.

Inspections should also include testing the smoke detector and checking to see if the battery is missing or in need of replacement. Hard wiring the detector in addition to the battery back-up might be a solution.

Here’s another mistake. While under way, the engineering staff either chocks open or ties back the watertight doors at the deck level to help vent the heat and bring in some relieving fresh air.

What if the water conditions are rough or your vessel is going through maneuvers (downstreaming) which may cause your vessel to heal over to the side? In those conditions it may not be cool air you are letting into the engine room but enough water to flood the engine room and sink your vessel.

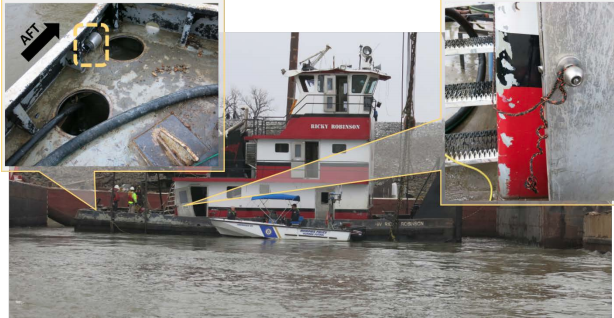

Here’s a quote from a NTSB report on the "Flooding and Sinking of Towing Vessel Savage Ingenuity" (Accident no. DCA17FM026):

“Given the vessel’s low freeboard, water washed onto the main deck, reaching the sill of the open engine room door, and down flooded into the engine room. Once water continuously flooded into the engine room, the list increased, and the engines stopped operating. The flooding overwhelmed the towboat’s reserve buoyancy, causing the vessel to sink. On towboats, doors to the engine room are often left open to allow for cooling and circulation.”

Workboat crews have a hard and dangerous job. Please don’t take a short cut that may cut short your career and maybe your life.

Stay safe and tight lines.

Tom Guldner of Marine Firefighting Inc. is a retired lieutenant from the New York City Fire Department's Marine Division. He held a Coast Guard license as a ships master and is certified as a fire instructor in New York and nationally. He has also trained firefighters and mariners in Canada, Mexico and Australia. You can contact Tom at [email protected].